Flue Gas Desulfurization (FGD) Plant

All over the world, more than 75% of electricity is generated from thermal power plants and coal contains Sulphur in the range of 0.3%-1% depending upon the origin location. Whereas, in some regions, Sulphur content is up to 1.5%. In thermal power plants, Sulphur (present in coal) reacts and form Sulphur dioxide (SO2), which is very harmful to the environment. So to save our environment, many countries like the US and European countries have stringent regulations that the discharge of Sulphur dioxide (SO2) should be less than 0.05%. For this, power plants are installing Flue Gas Desulfurization Plants (FGD) or units.

Processes of Flue Gas Desulfurization (FGD) Technology: Limestone Scrubbing

- Limestone slurry is sprayed on the incoming flue gas. The Sulphur dioxide gets absorbed. The limestone and sulfur dioxide react as follows : CaCO3 + H2O + 2SO2 ----> Ca+2 + 2HSO3- + CO2

CaCO3 + 2HSO3- + Ca+2 ----> 2CaSO3 + CO2 + H2O - A process improvement called forced oxidation further oxidizes the calcium sulphatic to Calcium sulphate in the following reactions CaSO3 + H2O + 1/2 O2 ----> CaSO4 + H2O

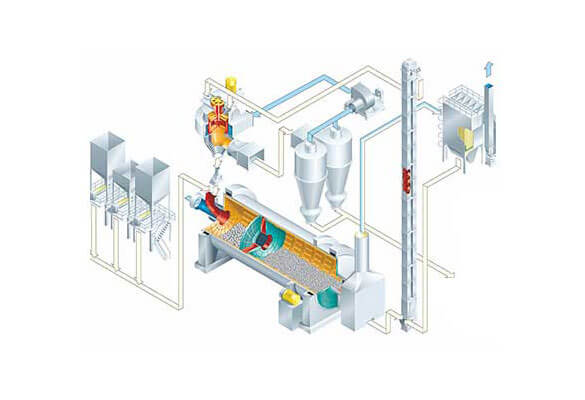

CPG PROVEN AND RELIABLE GRINDING SOLUTION FOR FLUE GAS Desulfurization PROJECT

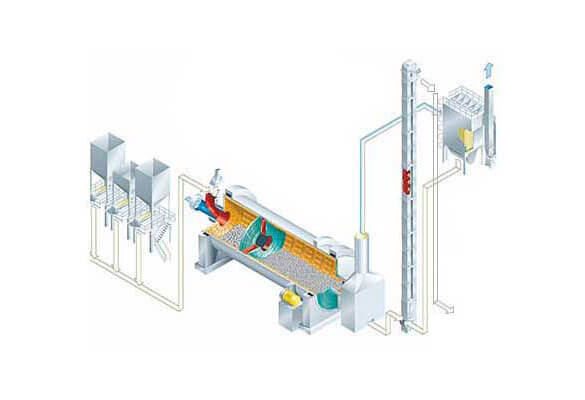

Our Limestone Grinding Circuit

We provide both wet and dry grinding circuits. And we are a leading supplier of ball mills, rod mills and classifiers. We have supplied more than 200 mills around the globe.

- Know More :

- Grinding Solutions

- Ball Mill

- Classifier

For limestone grinding, among our supplies, few were open circuit rod mills, close circuit dry grinding ball mills with double deck screens and dry grinding ball mills with air-swept circuits.